Composite construction is arguably going to be the future of caravan manufacturing. In fact, fibreglass sandwich panels are expected to become the norm within the next five years. Why? Well, they’re lighter, stronger, provide excellent water resistance and better insulation, to name a few benefits.

The application of fibreglass panels to industry is nothing new. Truck bodies, large motorhomes, trains… they’ve all employed such construction in one form or another for many years.

However, it’s fair to say that it has taken longer to be adopted by caravan manufacturers. Meranti timber or aluminium clad with ribbed or smooth aluminium is still widely in use, while some manufacturers instead opt for structural composite aluminium panels.

So fibreglass has not exactly ‘swept’ the industry. Instead, it has crept in, employed by savvy manufacturers with discerning customers. One such manufacturer is Crusader Caravans. Crusader Caravans saw the writing on the wall about five years ago. The Chameleon was its first caravan range to get the all-fibreglass treatment, and this continued with the compact CRV range released last year.

Given Crusader Caravans’ history with fibreglass sandwich panels, we jumped at the offer of an in-depth tour of the factory. We wanted to see exactly how these panels locked together to form a caravan body atop a chassis. Further, we wanted to see how these panels were made – and access was granted.

UNDERSTANDING COMPOSITE ’GLASS PANELS

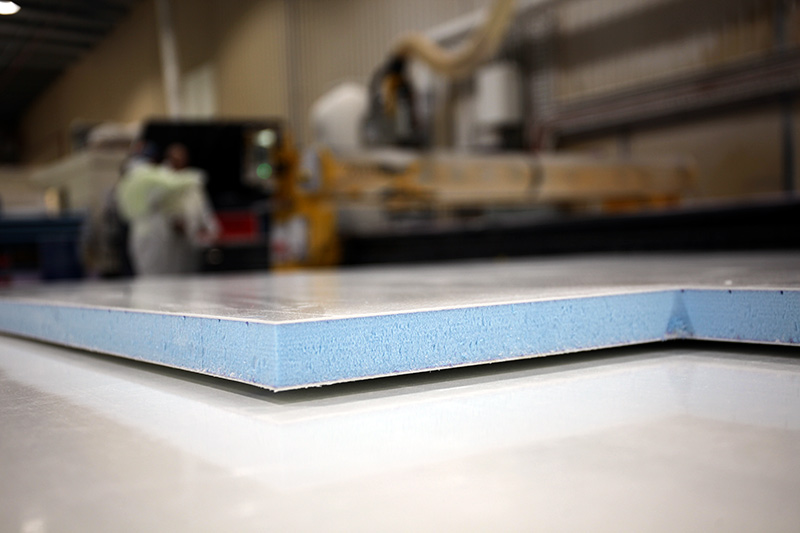

First, what is a fibreglass sandwich panel? The clue is in the name. Picture three layers comprising two outer skins of fibreglass – the bread – and an inner layer of structural XPS foam – the filling of the sandwich. XPS stands for eXtruded, high strength, closed-cell PolyStyrene.

When done properly, the result is a panel with an impressive ability to withstand tensile, shear and compressive forces. A high strength-to-weight ratio is a key benefit, too, as is the fact that these panels contain no joins, which in turn minimises the amount of joins required for the completed caravan. Fewer joins obviously reduces the potential for water ingress

Composite fibreglass panels also offer better thermal efficiency than a ‘stick and tin’ van. In fact, according to Crusader Caravans, the CSIRO tested the ‘CompLite’ panels supplied by Creative Composites, a nearby company specialising in fibreglass sandwich panels, and found them to be up to 1000 times more thermally efficient than ‘traditional’ construction materials.

In off-grid situations, anything you can do to decrease the burden on the gas cylinders or batteries is a good thing.

Composite panels such as these also remove the need for an aluminium or timber frame – they have their own structural properties. The absence of a timber frame means no chance of rot. Finally, they better suppress outside noise. While they’re not completely soundproof, any noise from outside will be much quieter – fantastic when staying in crowded areas.

BUILDING CRUSADER CARAVANS

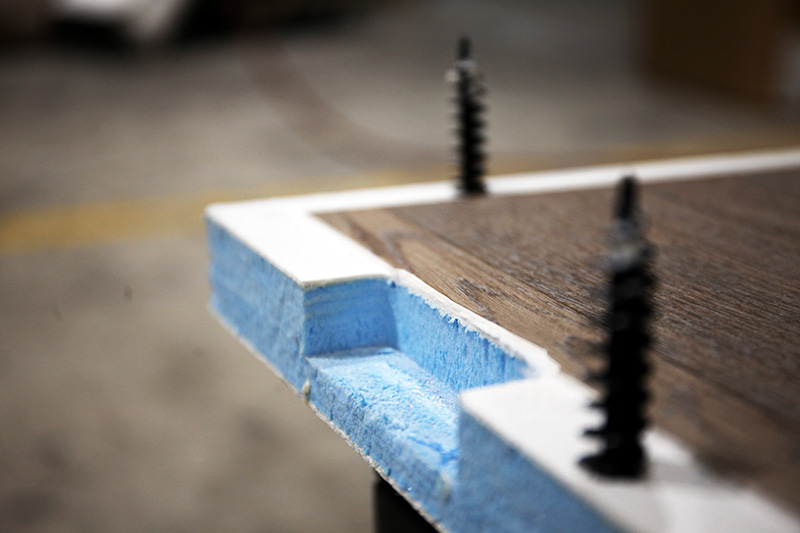

A couple of things stood out as we were shown through the Crusader factory. I was particularly intrigued by the company’s method for joining the wall panels to the one-piece floor and roof. Each side panel is CNC-routed by Creative Composites before delivery. They have a single protruding ‘tongue’ on the top and bottom.

These tongues lock into a notch routed into the floor and one-piece roof sections. This system guarantees that the wall panels will be accurately located. The walls and roof are 30mm panels comprised of outer layers of fibreglass and an XPS closed cell foam core.

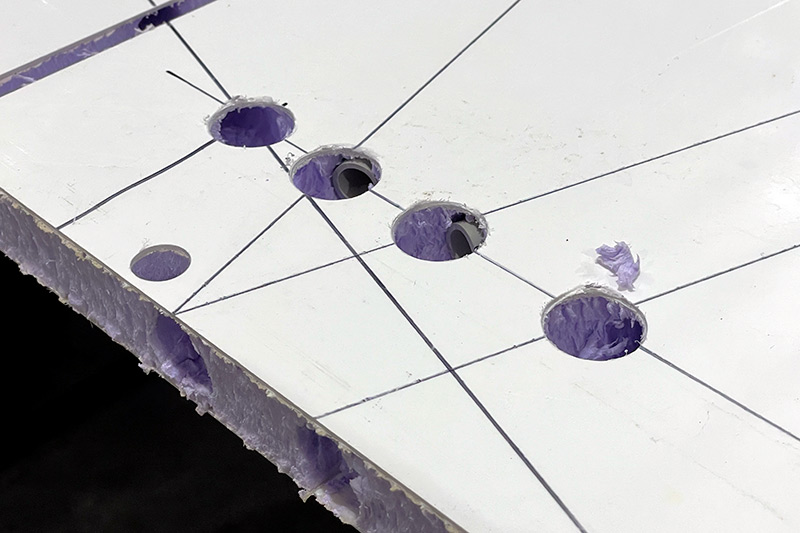

The panels, roof and floor are also routed with screw holes. But how do these screws guarantee strength and stability when they’re only biting into the closed-cell foam core of the sandwich panels? Well, it’s not only the screws doing the work: Crusader Caravans uses a special MS Polymer adhesive that’s also used by a major truck manufacturer to forever bind the structure of the caravan. The screws merely ensure a tight fit while the adhesive cures. Interestingly, Crusader manufacturers its own screws for this purpose.

It’s the same deal with the internal cabinetry. Were you to peak inside the overhead cabinets of, say, a CRV, you’d see screws; however, their chief purpose is to hold the cabinets in place while the adhesive goes off. The rest of the furniture is self-supporting, though it’s further secured by the adhesive.

Crusader was keen to point out its new flooring system, too. Whereas previous floors were a plywood/closed-cell foam/fibreglass matrix, the company is moving to a 40mm panel comprising two outer woven-fibreglass skins and a 40mm XPS closed cell foam core. This woven-fibreglass is specially sourced and built by Creative Composites.

The benefits are two-fold: the woven fibreglass provides even greater strength than the previous skin, while replacing the plywood with fibreglass will make Crusaders truly timber-free caravans.

With all fibreglass sandwich panels supplied exactly to size, with all required apertures for windows, hatches, etc., routed by Creative Composites, how does Crusader run the electrical wiring? When it comes to the wiring process, Crusader Caravans has developed wiring looms and a centralised management system, keeping penetrations in roof, walls and floors to a minimum. This in turn ensures the integrity of all roofs, walls and floor panels. Crusader says this process gives the customer peace of mind, reassuring them that the thermal, sound, structural and servicing practicality is not compromised.

That’s where things become a little more low-tech, but it’s effective. Each panel is marked in pencil with straight lines to represent the wires.

Obviously there is a lot more to the construction of a Crusader caravan. But as our tour came to a close, I was left with a favourable impression. I could not fault the strength of the panels or the method by which the floor, roof and walls were locked together. I even noticed that the floor vinyl on a Chameleon under construction had been perfectly sized and adhered to the floor panel – Crusader doesn’t ‘float’ the vinyl as some manufacturers do.

While production isn’t automated – caravans are still largely hand-built items – the precision of the CNC-cut fibreglass panels removes practically all potential for human error in terms of construction of the outer shell. Anyone who thinks these vans are slapped together should probably take a factory tour too.

TOURING CREATIVE COMPOSITES

Following our visit to Crusader Caravans, I was shown through Creative Composites. Having always been intrigued by how fibreglass sandwich panels were made, I was looking forward to this part.

Unsure what to expect, the first thing I noticed was the tidy presentation of the factory. Everything had its place. I was shown 60m rolls of fibreglass skins imported from Italy, and neat stacks of the closed-cell structural foam that would become the core of each sandwich panel, imported from Germany.

To begin, the fibreglass skins are laser-cut to length on a large, purpose-built bench. From there, two methods are available to create a sandwich panel: vacuum pressing, and a special method known as ‘hot melt’. To meet Crusader’s needs, Creative Composites uses hot melt. Creative Composites reasonably wanted to keep this process ‘secret’, so we were only shown the final stage.

Regardless, I was told that this process ensures consistency, reliability and quality. While the adhesive used to bond the two skins to the core is 90 per cent cured by the time it leaves the machine, Creative Composites leaves each panel for 24 hours before moving it to the final stage of the process: CNC routing.

If you’re unfamiliar with CNC, it stands for computer numerical control. It’s an automated process in which a machine drills and cuts according to specs fed to it by a computer. That is a very basic explanation, of course, but the result is a final product so precise that it could barely be replicated by the most expert tradesperson. It’s much faster than any human, too.

LOOKING FORWARD

I left Creative Composites with the same impression I had when leaving Crusader Caravans. This was a company serious about its work and meeting high quality standards. It’s fair to say that my pre-conceived notions of fibreglass sandwich panels being the future of caravan manufacturing were only confirmed.

Does ‘stick and tin’ manufacturing have a place in the Australian caravan industry? Yes – for now. Caravans have been built this way for decades and, when built, sealed and maintained properly, they’ll last a lifetime.

However, it’s just a fact that the benefits of composite panels far outweigh those of any other mainstream manufacturing techniques. Composite will become king.